1/2 HP, 6" WHEEL, 3450 RPM, 60 Hz, 110V, 4 Amp, Single Phase. Four amps is good for a 6" wheel grinder. That is about the top of the range for similar. But it does have a 1/2" shaft and some are 5/8". As long as its not bent it should not much matter.

Did not find a start cap under the base. Took the end bells off and it looks like the bearings have been spinning on the shaft. Replaced them and it started although sluggish. I vibrated a lot as expected. Forgot to look for the cap inside the bells. Will be taking it apart again so not a problem.

Grinder with old bearings and cup wheel.

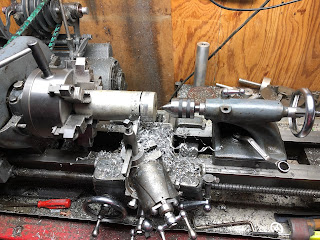

I plan to use this unit with the pink cup wheel. The hole in the wheel is 20mm and the shaft is 1/2". So I turned a bushing on the Atlas. The OD came out great but the ID reamed out a bit larger than I was shooting for. Still might work. If not easy enough to make another.

Next: turn the flanges/washers that support the stones. But first I need to recheck the motor shafts to ensure they are uniformly 1/2". Seen on YouTube where this is not always the case. Have also seen distortions where the flange rests from abuse. Need to check that too.

Took some scotch brite after the shafts this morning. Used the 10ths indicator on the left side. Did not have a good mount for the motor but it looks like it is within 2 or 3 th's. Way good enough.

Hand tightened the wheel between 2 of the factory sheaves without additional cardboard for cushioning. Flipped it on and it vibrated like crazy so I quickly shut it down, did not get to full speed.

The plan is to make a new sheave for the backside and incorporate the bushing into it to make it as long as possible. This will ensure alignment between the sheave and the shaft. The sheave will be fixed perpendicular to the shaft. Then any runout will be due to the stone.

I know I have a 10 under reamer. I may use it by hand after drilling the next size under 1/2. Have to look at the boreing bars. It would be even better if I could bore it.

The plan is to do all concentric operations without flipping the part. Hogged off most of the material then switched to a threading tool to relieve the back and define the intersection between the hub and sheave. The OD of the hub is such that the stone will go on but its too tight. Don't want to sand it to get the last bit because I want it to stay as concentric as possible.

The plan is to do all concentric operations without flipping the part. Hogged off most of the material then switched to a threading tool to relieve the back and define the intersection between the hub and sheave. The OD of the hub is such that the stone will go on but its too tight. Don't want to sand it to get the last bit because I want it to stay as concentric as possible.

No comments:

Post a Comment